An Unbiased View of 24??media

24??media for Beginners

Table of Contents24??media Can Be Fun For EveryoneA Biased View of 24??mediaThe 24??media DiariesThe smart Trick of 24??media That Nobody is Talking AboutThe Definitive Guide for 24??mediaGetting My 24??media To Work

This is just possible with Digital Printing, and it brings about a new degree of customization. Litho Lamination (Offset Printing) is a conventional printing approach and was one of the most popular option till recently. Litho is the process of printing onto a paper lining board, and then laminating flooring that onto corrugated.Right here are several of one of the most remarkable ones: Although various other printing kinds, like countered and display, can generate high quality, digital printing offers excellent outcomes. Unlike a few other methods, the top quality of an initial item coincides as the last. The digital printing procedure includes a straight transfer of the ink to the substratethat's why it's much quicker than various other printing choices.

Digital printing is extremely economical. When it comes to customising a print job's last product, digital printing is fast and versatile.

24??media Fundamentals Explained

That's why digital printing is a favored approach for unstable printing tasks. Digital printing entails pressing a couple of buttons and getting an outcome within seconds. It does not require any type of unique skills or expertise to obtain the job donethe procedure is fully automated. Digital inkjet printing reduces the amount of waste due to the fact that it only sends out ink to the parts to be published.

While digital printing is extremely helpful, other techniques are still in use. Countered printing (or offset presses) is a traditional printing approach.

The Definitive Guide to 24??media

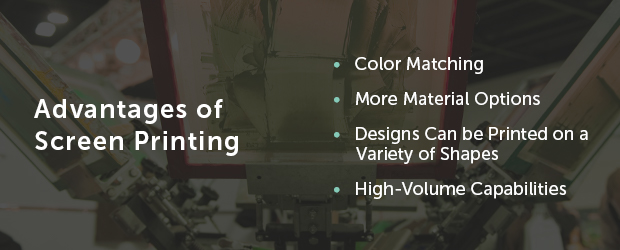

Display printing doesn't apply stress to the material. That's why it's usually utilized for printing on delicate substratums like balloons or thin textiles. Custom Boxes. A more vibrant, saturated, and intense finishBetter colour matching capabilitiesCost-efficient for huge batches Made complex and time-consuming setupHigh prices for low-volume printingOnly one style per batchResolution of photos is typically reduced quality

The printer sprays countless small ink beads externally to produce the desired photo. Today, commercial inkjet printer technology is changing standard high-speed printing presses.: Laser printers use a laser to transfer the digital image to the surface area. The laser relocates back and forth to create static electrical power throughout the printing procedure, launching the warmed printer toner onto the surface area.

Digital printing is evolving promptly. By taking complete advantage of digital printing capabilities, you can develop high-grade items and advertising materials while supporting the credibility of a modern company.

When intending for your organization's functional or marketing print product, it is important to select the most effective kind of printing approach. Variables that go right into determining the print process a job needs will certainly be discussed in this post.

Examine This Report on 24??media

This printing process is generally made use of for smaller sized tasks with a fast turn-around time. Balanced out printing is the process where the picture is moved from a steel printing plate to a rubber blanket, and afterwards to the paper to produce a top notch, clear photo. Offset printing is made use of for bigger projects that need exact colour representation.

Estimates can vary based on a job's demands, a handy guide to choosing which printing process your job requires is to compute run length. If your job needs much less than 1,000 duplicates, it may be best to publish using digital presses. If the project requires greater than 1,000 copies printed, it may be much more cost-effective to make use of countered printing.

Digital printing has a reduced set up price and a high run-cost, meaning it is the best printing technique for much shorter runs. The factor that digital printing has a low set-up expense is due to the fact that plates do not need to be made and examples do not have actually to be printed. Nevertheless, the printer toner that digital presses use is expensive, which is the factor why it has a greater run-cost.

Balanced out presses are made for jobs with lengthy runs since they have a high set-up expense and a reduced run-cost. The reason that balance out printing has a high set up price is because the press needs big metal plates to be made in order to transfer the picture. It has an intensive cleansing and upkeep process that requires to be done between different tasks.

8 Simple Techniques For 24??media

Therefore, the much more you publish, the a lot more affordable this procedure is. Examples of balanced out printing projects generated at Printing Unlimited. During the printing process electronic presses, like laser printers, make use of toner for the production of colour. Nonetheless, there are some larger electronic presses that make use of fluid ink. The objective of digital printing is to generate top quality, inexpensive pictures at a fast turnaround time.

Factors of personalisation can include a text, photos or colours that associate with the customer's interest. There is a wide array of substrates that can be made use of when publishing electronically on a flatbed press. Custom Printed Packaging. Using our electronic printers, we are able to publish on almost any type of substratum up to two inches thick

Discover Phillip Akhzar's trip, the Owner and CEO of Arka, bringing 16 years of knowledge in product packaging and supply chain logistics. Find out more on Arka. Screen publishing a long-lasting conventional print strategy, has weathered the evolving print landscape gradually; this approach involves transferring ink with a mesh display onto a surface, generating vibrant and sturdy prints.

In spite of its advantages, screen printing has limitations. While succeeding in strong designs, screen printing might have a hard time with fine information and complex patterns, a consideration for projects demanding high details.

The smart Trick of 24??media That Nobody is Discussing

Quick Turn-around: Since digital printing is fairly faster compared to the standard techniques, no time at all will be used up by display preparation, consequently, making it suitable for the conclusion of time-bound projects that may require amendments at the last min. Versatility in Products: Making use of digital printing, one can publish on products like paper, fabric, plastic, and lots of others.

Minimal Color-Matching: When it come to color, electronic printing can not exactly duplicate the shades made use of much like in traditional display printing. This restriction will certainly influence right here work requiring a best suit with the colors used in the screen printing procedure. Long-Term Resilience: Having the capability to publish in a fashion that is both vibrant and comprehensive, one may suggest that the lasting durability of these prints on specific materials can be doubtful, with several celebrations having chosen screen printing for its more durable, lasting result.